Products & Technology

GLO

(LLO Alternative Technology)

What is GLO(LLO Alternative Technology)?

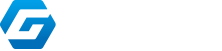

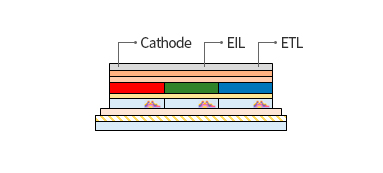

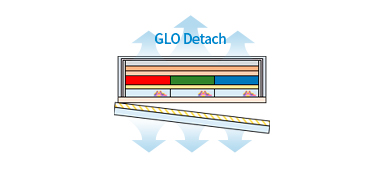

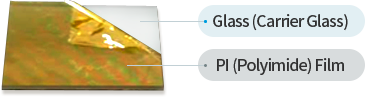

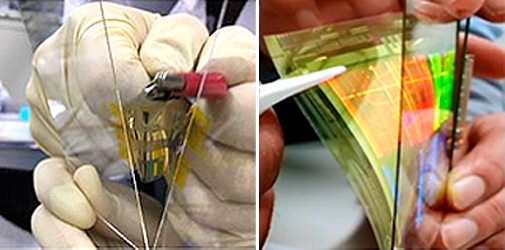

GLO transfers graphene for thin film separation between a glass substrate (carrier glass) and polyimide when manufacturing a flexible OLED, it refers to the process of separating a glass substrate (carrier glass) and polyimide using a porous vacuum adsorption method.

Differences from existing LLO processes

The existing LLO process of removing the front edge film using laser has disadvantages such as the high maintenance cost of receiving laser source from overseas, discolouration caused by soot caused by ablation, and cost of using expensive laser equipment. In contrast, GLO reduces maintenance costs in equipment processes and separates them by physical force, which does not affect finished OLED panels, resulting in a significant reduction in process yield and initial facility investment costs.

LLO

- High maintenance cost

- Ablation results in discolouration

- Use of expensive laser equipment

GLO

- Reduce maintenance costs

- Physical separation

No effect on OLED Panel

No effect on OLED Panel - Significant reduction in initial facility investment costs

- Electrostatic reduction effect

LLO

- High maintenance cost

- Ablation results in discolouration

- Use of expensive laser equipment

GLO

- Reduce maintenance costs

- Physical separation

No effect on OLED Panel

No effect on OLED Panel - Significant reduction in initial facility investment costs

- Electrostatic reduction effect

-

PI Printing

-

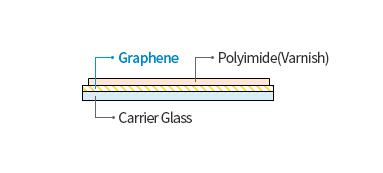

TFT Backplane Process

-

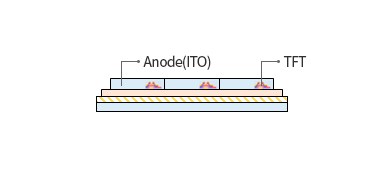

Plasma treatment

-

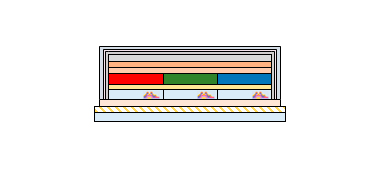

OLED Process

-

Encapsulation

-

Glass detach

Easy removal if graphene is coated

Graphene residue only on glass substrates

OLED test result