Products & Technology

-

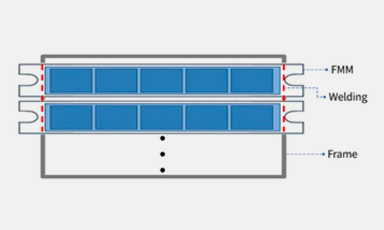

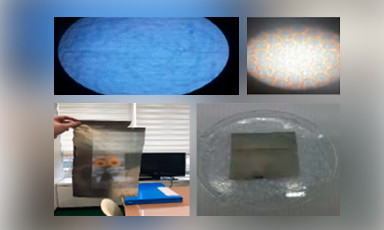

Example of FMM Caught by Jig

-

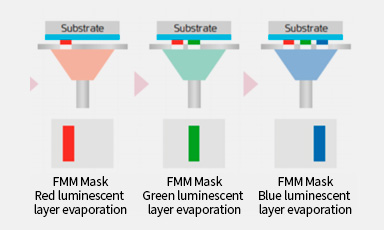

FMM Used for OLED

-

Graphene MSAP_FMM

Currently, the FFM market has problems such as W company's base substrate separation and plating quality problems, A company's Burr removal limit and Sharp adjustment problems, and D company’s over-etching and non-etching problems.

In contrast, GrapheneLab Co., Ltd. ensures high yield through a method of conductive material (CVD graphene) based on graphene.

Currently, it occupies the exclusive market of D Company in Japan, and export sanctions are being developed during the exclusive supply to S Company.

Two companies are under development in Korea, but they have no performance so far and are negative for the following reasons.

| Method | Issue | Possible Future | Strength / Developer |

|---|---|---|---|

| Based Graphene | Issue Expensive CVD graphene manufacturing equipment |

Possible Future Price lowered by mass orders |

Strength / Developer Method by conductive material(CVD Graphene) / GrapheneLab |

| Electro-forming |

Issue Issue about based board separationIssue about plating quality |

Possible Future Mass production limited by quality issue |

Strength / Developer W Company |

| Laser |

Issue Limitation in Burr separation Issue about adjustment of hall structure (sharp) |

Possible Future Market entrance is unclear due to fine pattern limitation for hall |

Strength / Developer A Company |

| Etching |

Issue Over-etching, under-etching |

Possible Future Market entrance is expected to be difficult due to the barriers of S & D companies |

Strength / Developer D Company |

-

01

Purpose

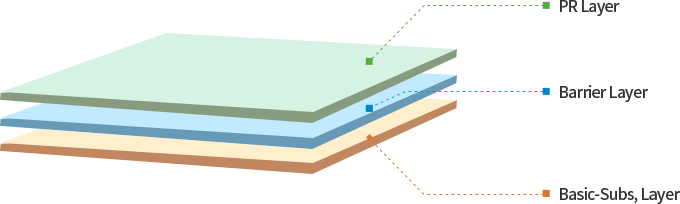

Electroforming with electrodes allows fine forming

Used as a base substrate when manufacturing a metal screen with a fine pattern

Improvement of a defect in electroplating peeling of fine PPI

-

02

Feature & Merit

Easy to form fine patterns

Electroplating Process Optimization Specifications

Easy to peel off metal screens with fine patterns below 30

Process yield can be 90% or higher when using electroplating substrates

Metal Screen During

the electroplating process Process yield Possible

More Than

90%